Our service for technicians

Are you a technician in need of analysis services from a testing laboratory for your company? We’re here to help! We have assembled the most important topics and links for you right here in one place, so you can access the pages that are relevant for you and request quotes as quickly as possible.

Our services – nine areas for first-class results

As one of the largest industrial laboratories for inorganic elemental analysis and powder characterization, ChemiLytics offers you a comprehensive resource for your laboratory services. With approximately 7,500 m2 of laboratory space, including a total of 1,000 m2 under clean-room conditions, we provide independent analytical services of the highest quality thanks to state-of-the-art equipment and qualified and experienced workers.

Sample receipt and preparation

In-house sample preparation, including sample division under clean-room conditions, ensures a high standard of quality and enables special services for our customers such as ultratrace analysis.

Classic wet chemical methods

Our wet chemical analyses, such as chromium (VI) determination, provide an essential support for control over other analytical methods and enable us to develop and verify new methods together with our customers.

Non-metal analysis

The assay of gases, carbon and sulfur accompanying production and technical processes enables our customers to increase quality and yield.

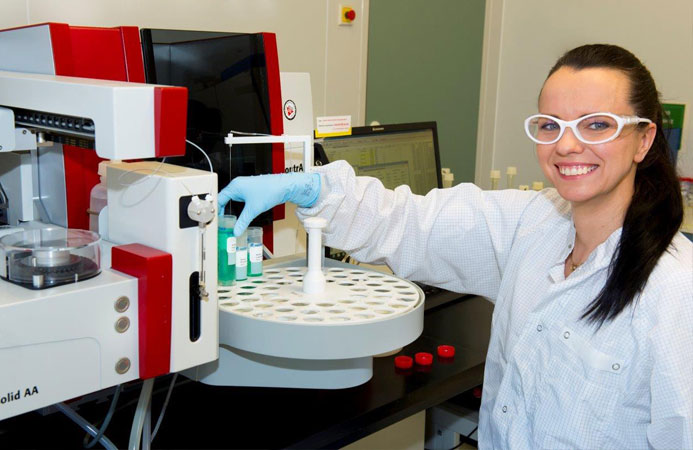

Trace elemental analysis

Trace elemental analysis enables our customers to verify their quality standards. Analysis using ICP-OES and ICP MS enables our customers to expand their product portfolio in applications with very high demands in terms of purity and quality.

X-ray techniques

ChemiLytics supports its customers from the beginning of the production chain: X-ray fluorescence analysis (XRF) and X-ray diffraction analysis (XRD) ensure precise assessment of raw material quality, which is crucial for problem-free production.

Powder characterization

Production-related and process-oriented analyses – such as particle/grain size distribution using laser diffraction or BET measurement – enable our customers, including those from the 3D printing sector, to increase quality and yield.

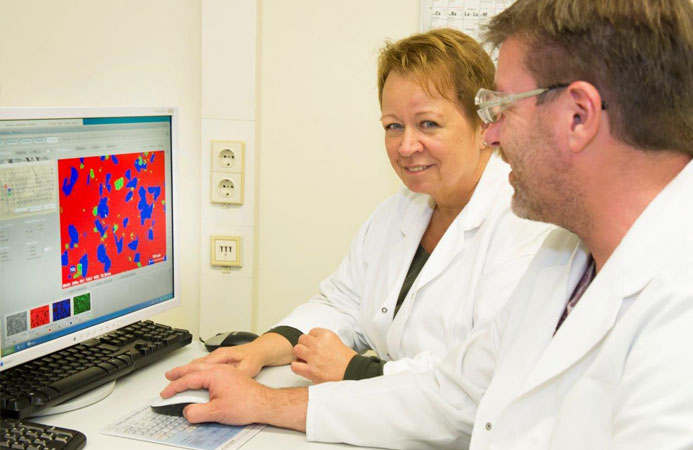

Scanning electron microscopy

On the one hand, our service supports the R&D activities of our customers, such as battery cell analysis for electromobility, based on state-of-the-art techniques for SEM/EDX analysis. It also includes damage analysis to deduce reasons for complaints.

Hard-metal laboratory

A highly customer-oriented service that supports our customers in many application-related analyses.

Gamma spectrometry

We offer our customers an analysis of raw materials and waste as the basis for the corresponding disposal certificate with regard to natural radioactivity.

Our list of services

For more information on the services we offer, take a look at our list of services. Here you can also inquire directly about our services.

Our accreditations and certification as a testing laboratory

Our customers in the international high-tech industry expect more than compliance with specification values: they want constant proof of quality in the form of actual product data from their current production operations. That requires complex, tailor-made analytics. We are able to provide reliable statements on every desired product feature in the shortest possible time, with expertise that has been proven by an independent institution in accordance with international criteria: ChemiLytics has been accredited as a testing laboratory in accordance with DIN EN ISO/IEC 17025 (formerly DIN EN 45001) since 1995.