Our processes and services

As one of the largest industrial laboratories for inorganic elemental analysis and powder characterization, ChemiLytics offers you a comprehensive resource for your laboratory services. With approximately 7,500 m2 of laboratory space, including a total of 1,000 m2 under clean-room conditions, we provide independent analytical services of the highest quality thanks to state-of-the-art equipment and qualified and experienced workers.

Nine areas where we offer analytical services

Thanks to a diverse range of equipment and qualified personnel, our laboratory offers a broad spectrum of services in the field of inorganic analysis. For a complete overview of the services we offer, take a look at our list of services. If you have specific questions on the scope of services authorized by our accreditation, please call +49 5321 751 51616 or email services@ChemiLytics.com.

Sample receipt and preparation

In-house sample preparation, including sample division under clean-room conditions, ensures a high standard of quality and enables special services for our customers such as ultratrace analysis.

Classic wet chemical methods

Our wet chemical analyses, such as chromium (VI) determination, provide an essential support for control over other analytical methods and enable us to develop and verify new methods together with our customers.

Non-metal analysis

The assay of gases, carbon and sulfur accompanying production and technical processes enables our customers to increase quality and yield.

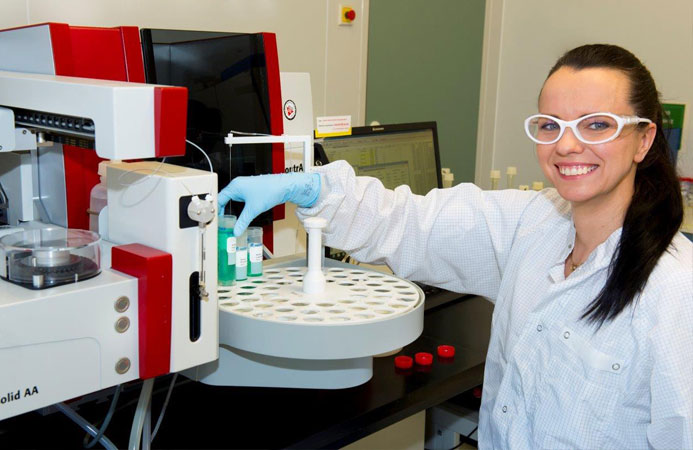

Trace elemental analysis

Trace elemental analysis enables our customers to verify their quality standards. Analysis using ICP-OES and ICP MS enables our customers to expand their product portfolio in applications with very high demands in terms of purity and quality.

X-ray techniques

ChemiLytics supports its customers from the beginning of the production chain: X-ray fluorescence analysis (XRF) and X-ray diffraction analysis (XRD) ensure precise assessment of raw material quality, which is crucial for problem-free production.

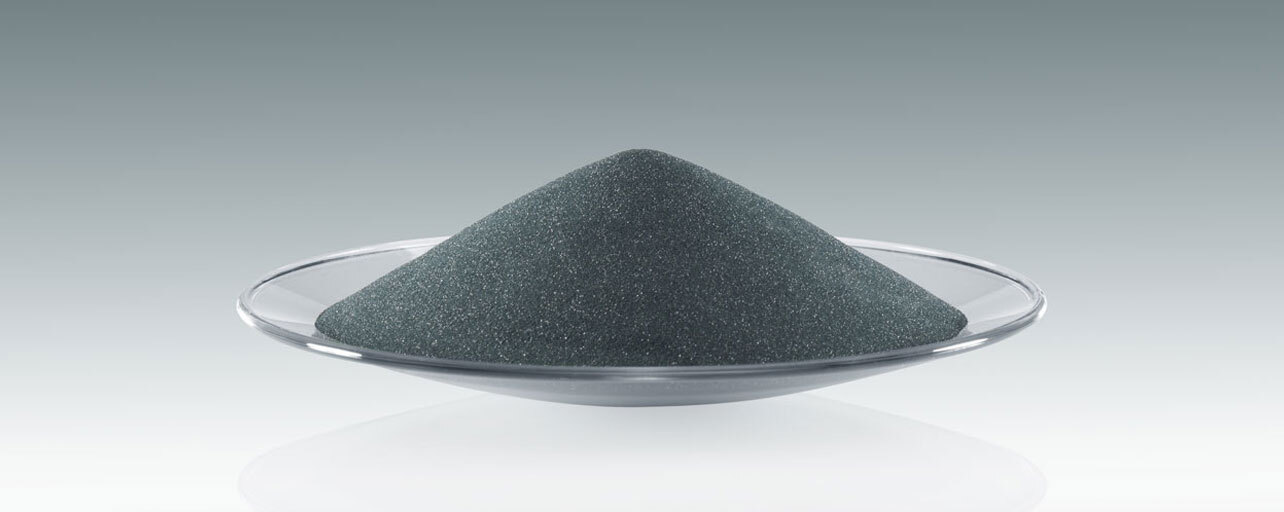

Powder characterization

Production-related and process-oriented analyses – such as particle/grain size distribution using laser diffraction or BET measurement – enable our customers, including those from the 3D printing sector, to increase quality and yield.

Scanning electron microscopy

On the one hand, our service supports the R&D activities of our customers, such as battery cell analysis for electromobility, based on state-of-the-art techniques for SEM/EDX analysis. It also includes damage analysis to deduce reasons for complaints.

Hard-metal laboratory

A highly customer-oriented service that supports our customers in many application-related analyses.

Gamma spectrometry

We offer our customers an analysis of raw materials and waste as the basis for the corresponding disposal certificate with regard to natural radioactivity.

From the sample to a flawless result

It takes three hours (or up to a maximum of 14 days) to analyze a sample, depending on the degree of complexity. The ChemiLytics portfolio covers a unique analytical spectrum. Typical samples include tungsten, tantalum and niobium ores, powder and scrap from refractory metals and samples from the recycling sector.

All over Europe / the world? Unique range of services and equipment

The ChemiLytics portfolio covers a unique analytical spectrum. Our cutting-edge methods are employed wherever there are high purity and quality requirements, for example in 3D printing or the manufacture of ultra-pure materials.

For comparable results – all from a single source

Our monitoring and process-engineering analysis enables us to support partners in diverse markets such as production, recycling and environmental monitoring. We offer complex, multi-step analysis from a single source, which saves our customers from having to ship samples multiple times and consolidate results from different sources.