Additive manufacturing

One important prerequisite for the industrial use of additive processes is knowledge of the quality of the material and the composition of both the material used and the finished product. As an accredited laboratory, we provide state-of-the art testing methods that help our customers solve a multitude of chemical analysis problems:

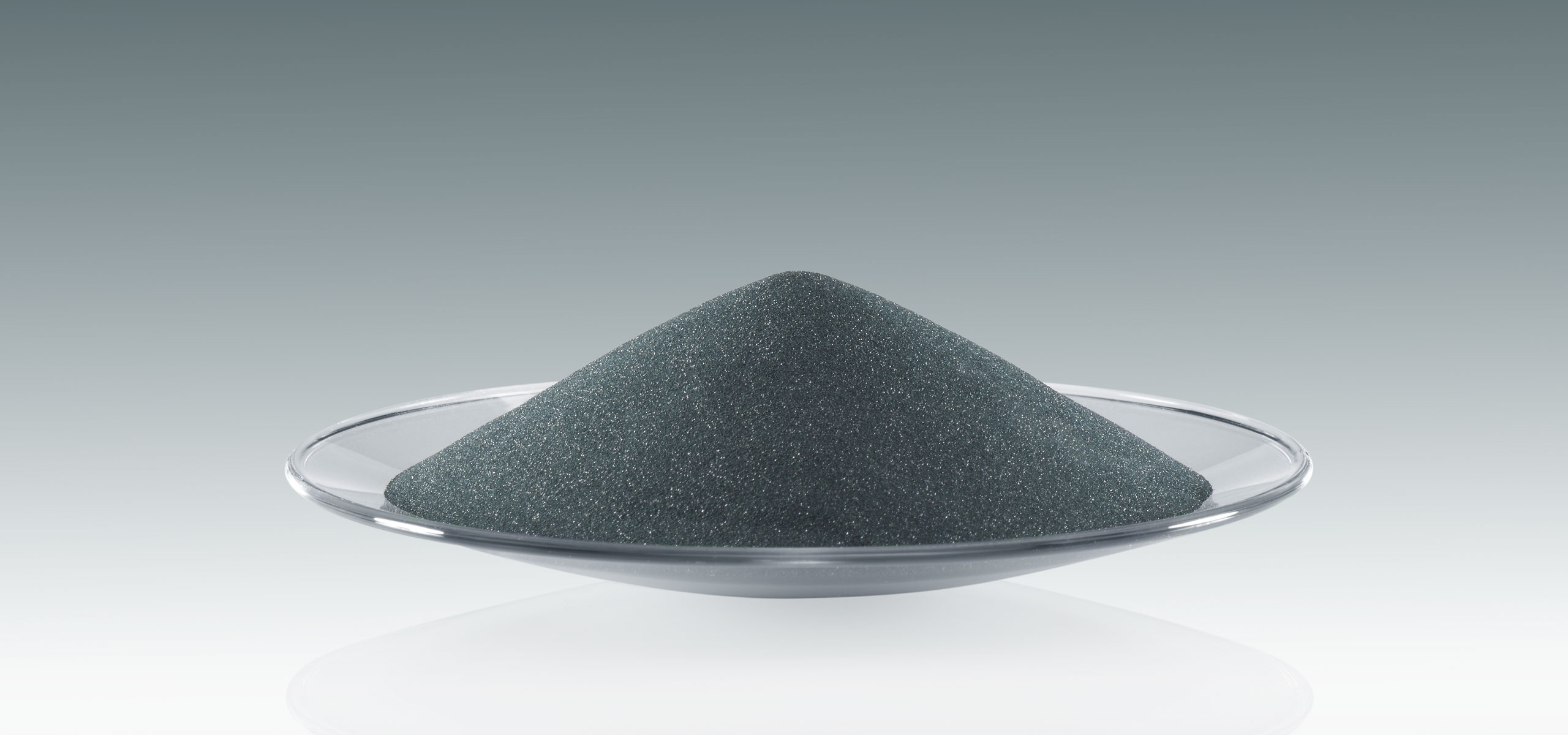

Powder characterization / preliminary product analysis

We offer our customers comprehensive services to ensure the quality and reliability of their powder materials for additive manufacturing processes. With state-of-the-art analysis techniques and expertise, we provide detailed information on particle sizes, particle shapes, bulk material properties, chemical composition, and more. You can trust in our expertise to take your additive manufacturing to a new level even before the actual production, thanks to powder characterization or preliminary product analysis.

We analyze:

- Particle size and shape

- Pore size distribution

- Bulk, tamped and particle density

- Flow rate

- Specific surface (BET)

- Crystallographic structure (X-ray diffraction)

- Elemental analysis (RFA, ICP OES/MS, AAS)

- Oxygen content (carrier gas hot extraction)

We analyze:

- Surface roughness/layer analysis/grain structure (SEM)

- Porosity/density

- Depiction of contaminations/cracks

- Elemental analysis (RFA, ICP OES/MS, AAS)

- Oxygen content (carrier gas hot extraction)

Finished parts analysis

Finished parts analysis is another area where we offer our customers analysis results of the highest quality for their additively manufactured parts. Our expertise and cutting-edge technologies enable us to conduct comprehensive studies of material composition, microstructure, surface quality, mechanical properties, and much more. Our detailed analyses help ensure the quality, performance and reliability of additively manufactured finished parts.

Our expertise for various markets

As a service provider in the analysis sector, ChemiLytics also offers services tailored to various markets. This means participants in battery recycling, additive manufacturing and recycling as a whole benefit from our expertise in the relevant analysis methods and from our support across entire production cycles and life cycles.