Qualität & Erfahrung im Bereich der Materialprüfung

ChemiLytics – Ihr Analytik-Zentrum in der Region Südniedersachsen. Das Labor gehört zur Masan Group und profitiert von jahrelanger Expertise im Bereich der chemischen und physikalischen Analyse.

ChemiLytics in Goslar ist eines der größten nach ISO 17025 akkreditierten Labore Deutschlands für anorganische Elementanalytik und Pulvercharakterisierung, womit wir weltweit Kunden u.a. aus den Bereichen 3D-Druck, Luft- und Raumfahrt und der E-Mobilität bedienen können. Auf insgesamt 7.500 Quadratmetern Nutzfläche erarbeiten hier etwa 70 Mitarbeiter chemische Analysen und physikalische Messdaten.

Proben in Perfektion

Mitarbeiter:innen

Unsere Leistungen – 9 Bereiche für erstklassige Ergebnisse

Als eines der größten Industrielabore für anorganische Elementanalyse und Pulvercharakterisierung bietet ChemiLytics Ihnen einen umfassenden Service für Ihre Labordienstleistungen an. Auf rund 7.500 m2 Laborfläche mit insgesamt 1000 m2 Reinraumbedingungen erbringen wir unabhängige analytische Dienstleistungen auf höchstem Qualitätsniveau dank modernster technischer Geräteausstattung sowie qualifizierten und erfahrenen Mitarbeiter:innen.

Probenannahmen und Probenvorbereitung

Die eigene Probenvorbereitung inklusive der Probenteilung unter Reinraumbedingungen sichert hohe Qualitätsstandards und ermöglicht spezielle Dienstleistungen für unsere Kund:innen wie beispielsweise die Analytik im Bereich der Ultraspuren.

Klassische nasschemische Methoden

Unsere nasschemischen Analysen, wie zum Beispiel die Chrom (VI)-Bestimmung, unterstützen essentiell die Kontrolle von anderen analytischen Methoden und ermöglichen die Entwicklung und Verifizierung von neuen Methoden zusammen mit unseren Kund:innen.

Nichtmetall-Analytik

Die produktionsbegleitende und verfahrenstechnische Bestimmung von Gasen sowie Kohlenstoff und Schwefel ermöglichen unseren Kund:innen, die Qualität und die Ausbeute zu erhöhen.

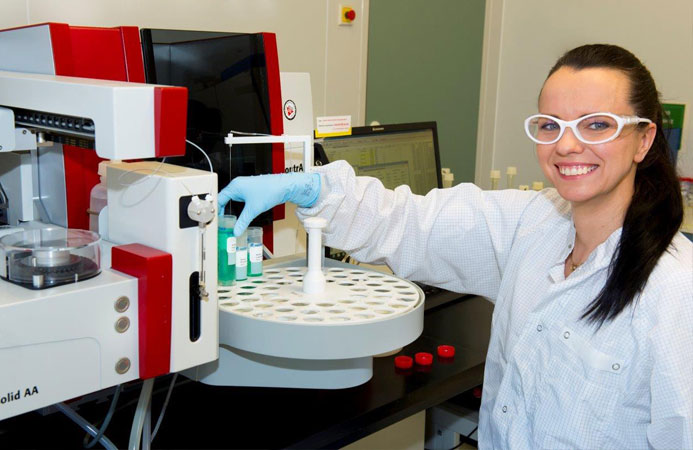

Spurenelementanalyse

Die Spurenelementanalyse erlaubt unseren Kund:innen, ihre Qualitätsansprüche zu überprüfen. Die Analytik mittels ICP-OES und ICP MS ermöglicht es unseren Kund:innen, ihr Produktportfolio in Anwendungen mit sehr hohen Ansprüchen in Bezug auf Reinheit und Qualität zu erweitern.

Röntgentechnik

Die ChemiLytics begleitet ihre Kund:innen vom Beginn der Produktionskette an: Röntgenfluoreszenzanalyse (RFA) und Röntgenbeugungsanalyse (RBA) sichert die präzise Einschätzung der Rohstoffqualität, welche entscheidend für eine problemlose Produktion ist.

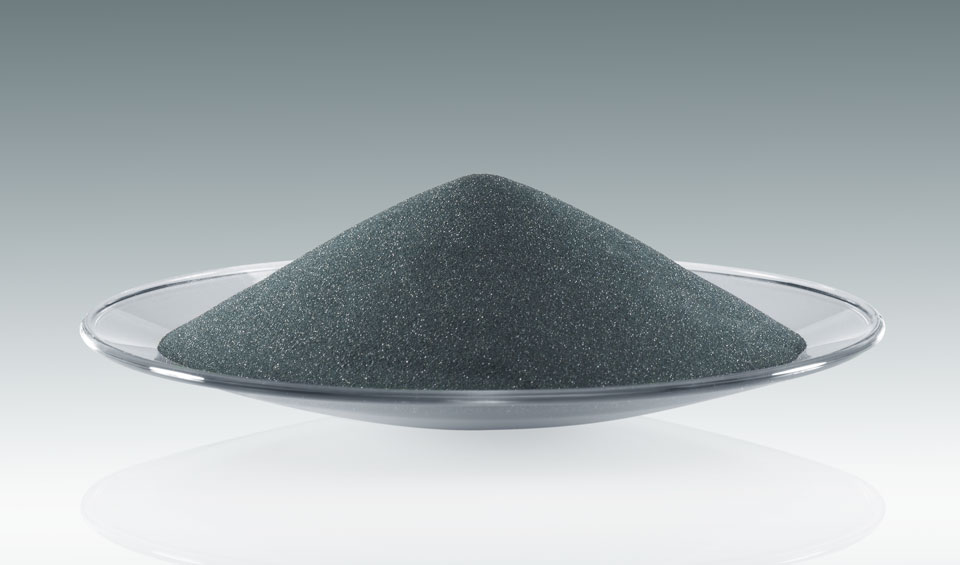

Pulvercharakterisierung

Produktionsbegleitende und verfahrenstechnische Analysen – wie die Partikel-/Korngrößenverteilung mittels Laserbeugung oder die BET-Messung – ermöglichen unseren Kund:innen, unter anderem aus dem Bereich des 3D-Drucks, die Qualität und Ausbeute zu erhöhen.

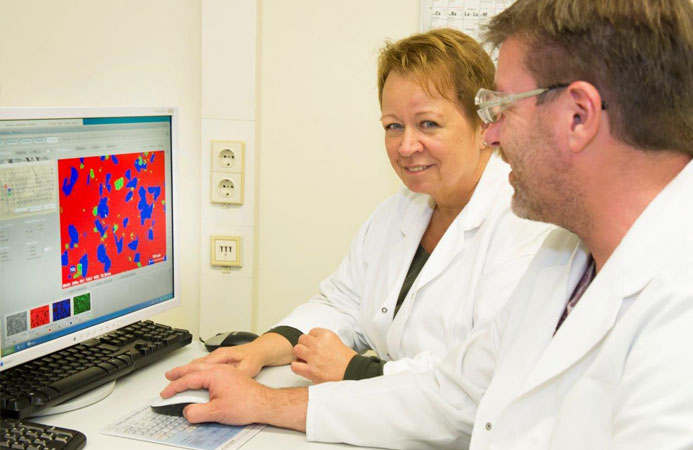

Rasterelektronenmikroskopie

Unsere Dienstleistung unterstützt zum einen die F & E-Aktivitäten unserer Kund:innen, zum Beispiel Batteriezellen-Analyse in der Elektromobilität, basierend auf modernsten Techniken der REM-/EDX Analyse. Zum anderen umfasst sie die Schadensanalyse, um Gründe für Reklamationen abzuleiten.

Hartmetall-Labor

Eine hohe kundenorientierte Dienstleistung, die unsere Kund:innen in vielen anwendungsbezogenen Analysen unterstützt.

Gammaspektrometrie

Wir bieten für unsere Kund:innen die Analyse von Rohstoffen und Abfällen als Grundlage für die entsprechenden Entsorgungsnachweise in Bezug auf natürliche Radioaktivität.

Unsere Expertisen für verschiedene Märkte

ChemiLytics bietet als Dienstleister im Analysesektor seine Leistungen auch speziell für verschiedene Märkte an. So profitieren Beteiligte beim Batterie-Recycling, in der Additiven Fertigung oder Recycling allgemein von unseren Expertisen in relevanten Analysemethoden und von unserer Betreuung über ganze Produktions- und Lebenszyklen hinweg.

Unsere Akkreditierung als Prüflabor

Seit 1995 ist ChemiLytics nach DIN EN ISO/IEC 17025 (vormals DIN EN 45001) als Prüflabor akkreditiert. Die Akkreditierung zeigt: auf unsere Prüfergebnisse ist Verlass. Unsere Kompetenz und ein normkonformes Qualitätsmanagementsystem wurden nach international festgelegten Kriterien durch eine unabhängige Institution nachgewiesen.